Mastering the Art of Blanching IQF Fruits & Vegetables

Consumers are becoming more and more interested in IQF fruits and vegetables since the shelf life is one of their top concerns. This is one of the factors contributing to Future Market Insights' forecast that the market will expand by roughly 3.6% per year over the next ten years. Thus, IQF processors need to stay current and use cutting-edge technologies to guarantee the greatest quality and maintain their competitive edge.

How to achieve premium quality IQF fruits and vegetables

In order to sell their products at a premium price, IQF processors must preserve the natural color, flavor, and texture of their fruits and vegetables. The key to achieving this is in the pre-treatment of the product, which involves a rapid-cooking process called blanching.

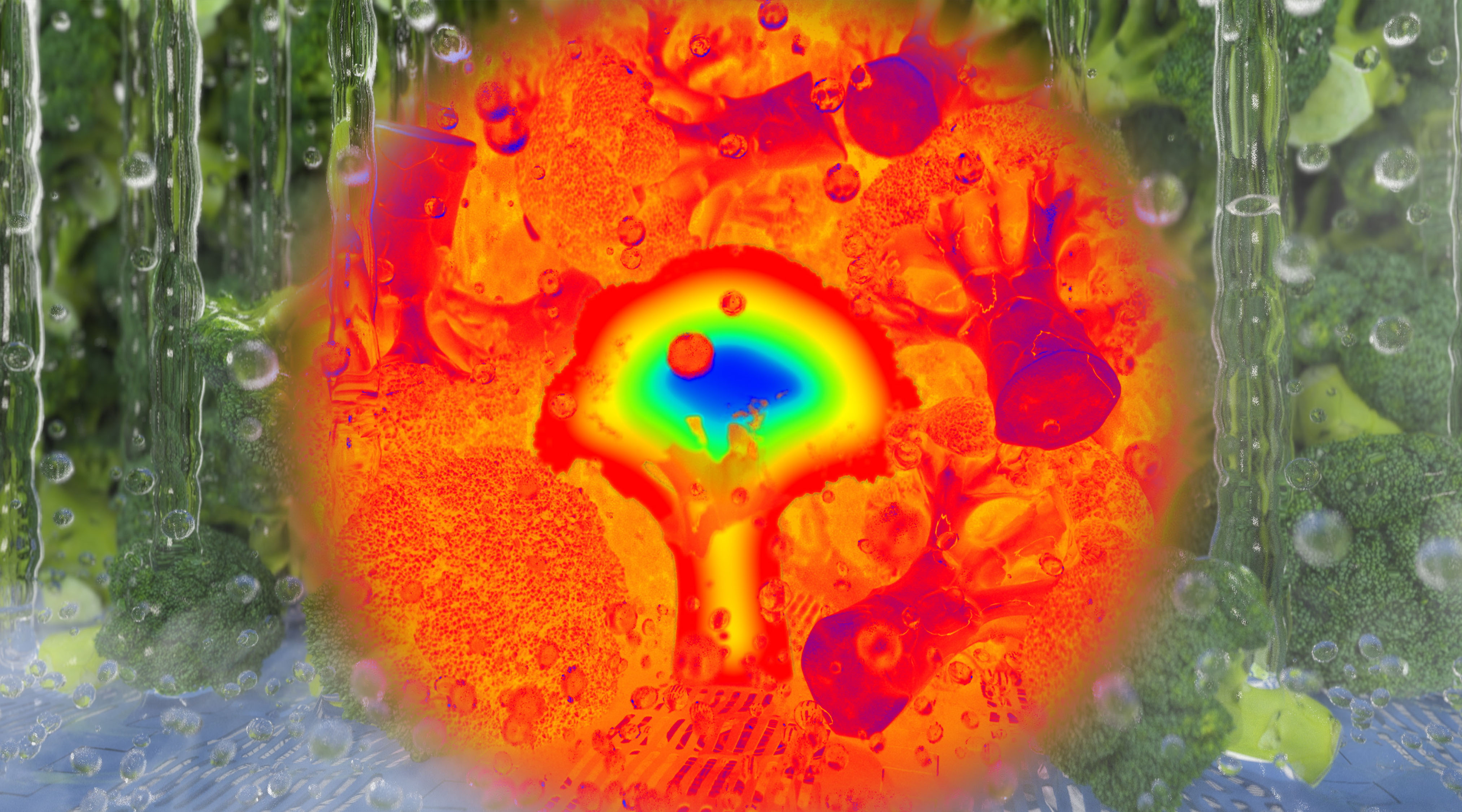

Blanching consists of showering the product with hot water at +95°C for a short period of time, after which it is cooled at +1°C and then frozen. During this process, heat deactivates enzymes that regulate biochemical reactions in living organisms and that cause loss of flavor, nutrients, or color change. These enzymes are responsible for the brown color that quickly appears on the fruit after cutting. If fruits or vegetables are not blanched, the enzymes are not deactivated and will continue to act slowly in the frozen product. For this reason, blanching is a key part of the preservation process, as it allows one to obtain a higher-quality final product.

High-quality blanching through impingement technology

Despite popular belief, blanching has more to do with appearance than it does with safety regulations, but it still improves the overall quality of the final IQF product. Controlling certain variables can make the difference between a good quality and a premium quality product. Temperature control is one of the most important.

When blanching, it is crucial to reach the optimal temperature and have total control over the blanching time. The reason for this is that over-blanching can weaken the product’s cellular structure, which results in the loss of vitamins, minerals, and flavor.

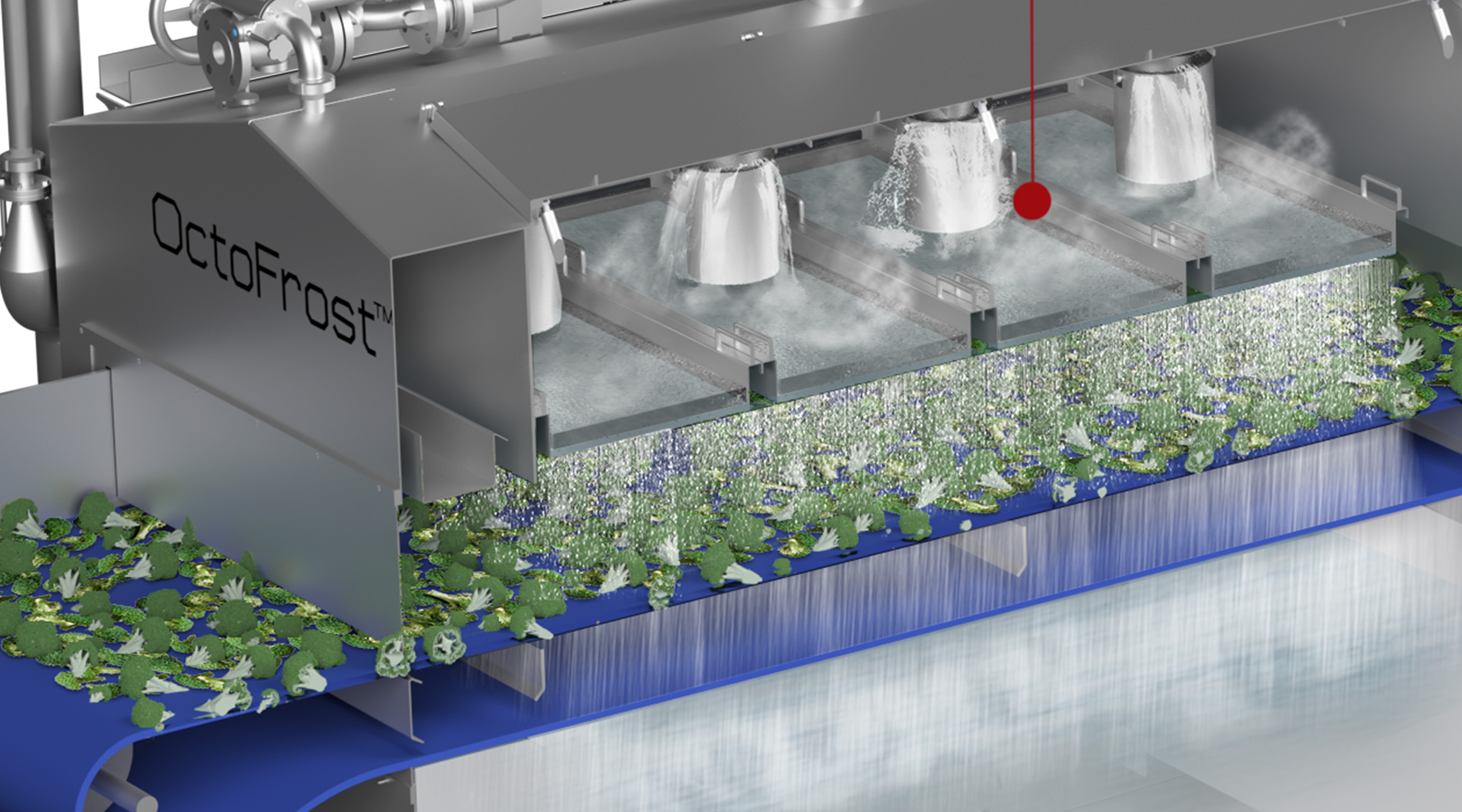

The newest technical advancement in the food processing sector is the OctoFrost IF Blancher. Its rainshower system allows the hot water to fall onto the product by means of gravity and break the layer of air surrounding it. This method reduces the blanching time to a minimum, preventing over-blanching and preserving the product’s appearance.

Why use the OctoFrost IF Blancher?

Steam injection has proven to be the best practice in the industry to heat the blanching water since it uses less energy than traditional methods. In addition, this method ensures the heat is completely absorbed into the water. Because effectiveness and energy efficiency are two of OctoFrost's top priorities, the IF blancher has been designed to achieve the quickest and most efficient blanching.

With the OctoFrost™ cross-flow water system, the water exits the machine right after showering the product and re-enters the water tank to be reheated by means of steam injection. By preventing steam leaks, this technique can reduce steam consumption by 30% to 40%.

In conclusion, the deactivation of enzymes during optimal blanching of IQF fruits and vegetables results in the highest quality results. This is accomplished by rapidly achieving the desired core temperature, followed by rapid cooling. This makes it possible to have complete control over the temperature at every stage of the process, which is accomplished using the OctoFrost IF blancher's several temperature zones.

Keeping up to date with the latest technological innovations in the food industry keeps you competitive in the current growing trend of the global IQF market. This is key to the long-term success of your IQF business.