5 Key Elements for Maximizing Energy Efficiency in IQF Freezing

As food processors navigate various challenges, one critical decision they face is selecting the most suitable and cost-effective Individual Quick Freezing (IQF) Freezer. The recent surge in energy costs has intensified the importance of this decision, prompting processors to actively seek energy-efficient IQF technology to minimize running costs.

In this blog, we delve into the five essential elements that drive energy efficiency in an IQF tunnel freezer: aerodynamics, fans, bedplates/conveyor belts, coil design, and housing/floor heating.

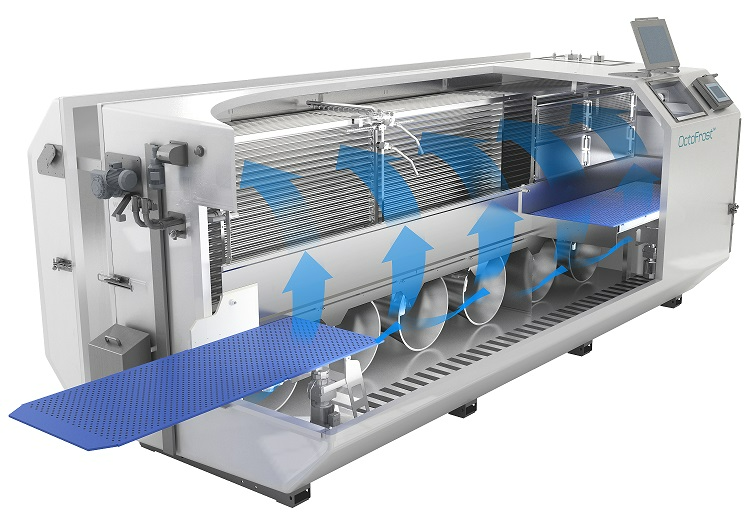

Accelerating Freezing with Advanced Aerodynamics

Aerodynamics, which refers to the study air movement around objects, significantly influences freezing quality and product dehydration. Achieving optimal aerodynamics involves a complex equation of the right pressure, air velocity, temperature, freezer design, and fan design.

The right combination also leads to fluidization, where the product behaves like a fluid and retains its shape during the freezing process. Other key benefits include in shorter freezing time, low product dehydration, maximum freezer capacity and superior product quality.

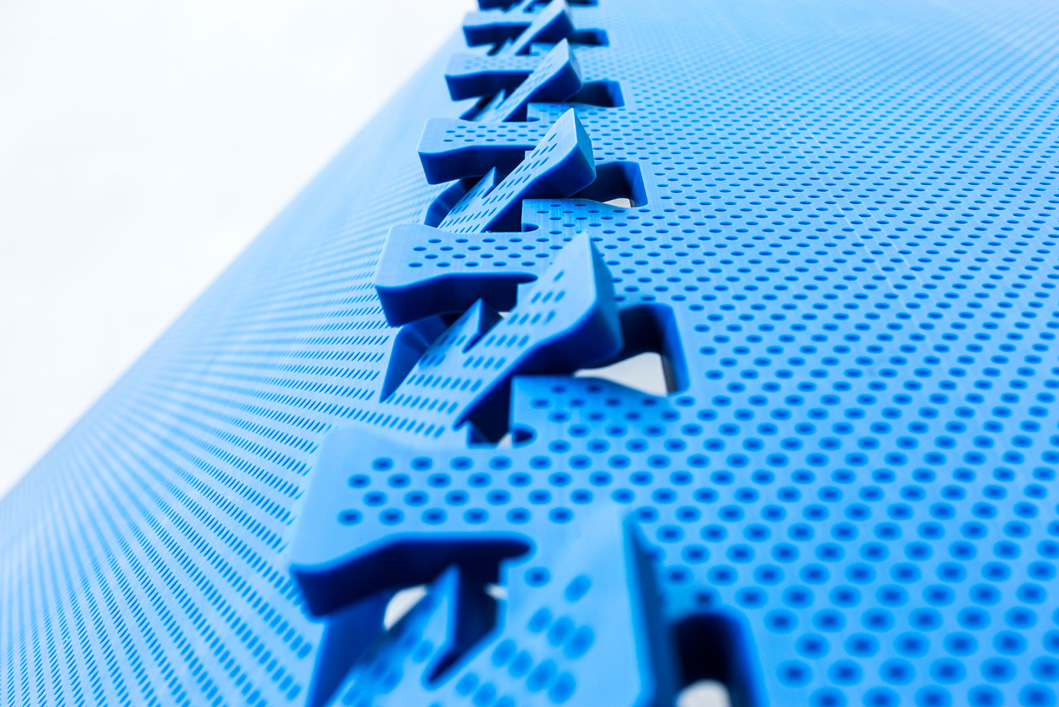

Optimal Fluidization with Patented Bedplates

Conventional freezers rely on conveyor belts, which create friction between the product and the belt and require additional energy to maintain proper cooling. In contrast, the bedplates are designed with precise thickness and hole configuration to facilitate the required fluidization. This innovative design minimizes energy consumption and eliminates product sticking, enhancing both efficiency and product quality.

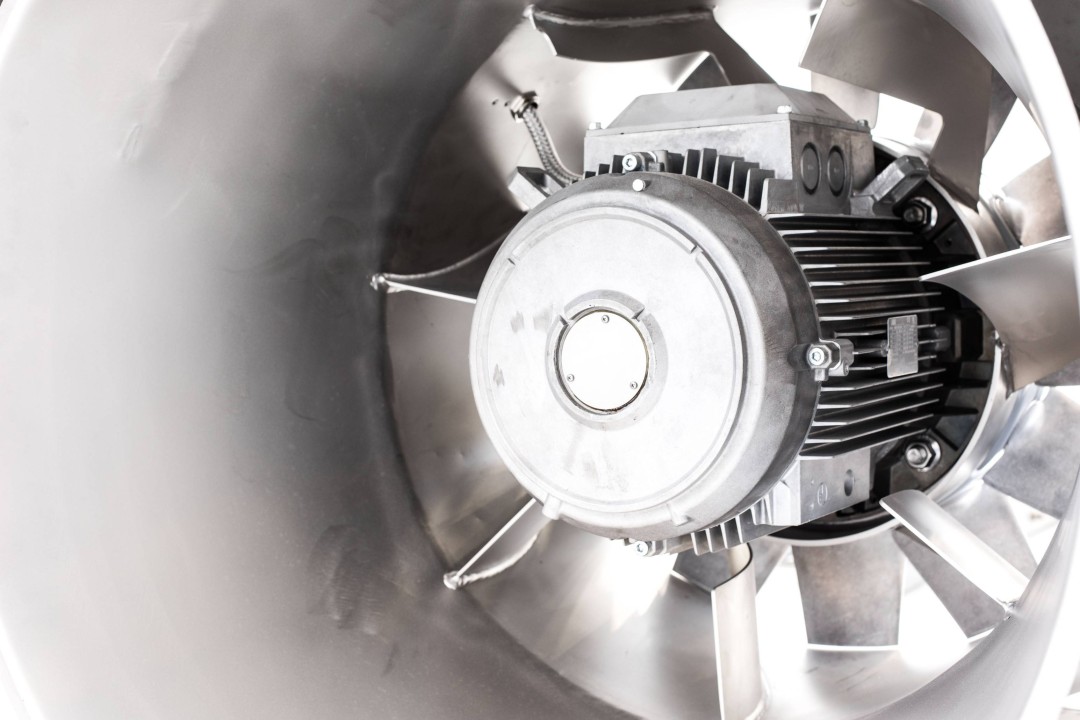

Flexible Fan Design for Energy Savings

Unlike traditional IQF tunnel freezers that often operate fans at full capacity, our IQF Tunnel features vane axial fans with adjustable speeds. This unique customization allows processors to optimize fan speeds based on the specific characteristics of the product being frozen. The intelligent fan design ensures efficient airflow control while preserving product integrity. By operating fans at typically 75% to 85% of their maximum capacity, significant energy savings of up to 30% can be achieved.

Extended Production Hours with Oversized Coil

The size of the coil within an IQF freezer determines the heat removal capacity. Employing an oversized coil enables the fans to operate at lower speeds while maintaining fluidization and desired cooling effects. Additionally, the increased frontal area of the coil extends the time between defrosting cycles, resulting in substantial energy savings and longer production hours.

Lack of Floor Heating

Unlike traditional IQF freezers that require floor heating to prevent freezing and equipment damage, the OctoFrost IQF Tunnel Freezer stands independently on supporting feet. This innovative design ensures excellent insulation, eliminating the need for floor heating. Removing this energy-intensive requirement enhances sustainability and reduces operational costs.

Invest in Energy Efficiency for a Sustainable Future

Amidst the energy crisis, investing in an energy-efficient IQF freezer is paramount for food processors seeking to minimize running costs. Addressing the five key elements of energy efficiency - efficient aerodynamics, optimal fluidization, fan design, oversized coil, and floor heating - will help you unlock optimal performance and cost-effectiveness for unparalleled efficiency, quality, and profitability in your IQF business.